VITVO 3D Cell Culture Bioreactor

Three Dimensional Platform

Three dimensional (3D) platforms have potential to provide more physiologic environments for cell culture in drug discovery and toxicology than classical 2D culture systems.

A Different Modulation of Gene Expression

The 3D culture of VITVO leads to a different modulation of gene expression, ultimately influencing the antigenic profile of the cells and closely mimicking an in vivo environment.

Overview

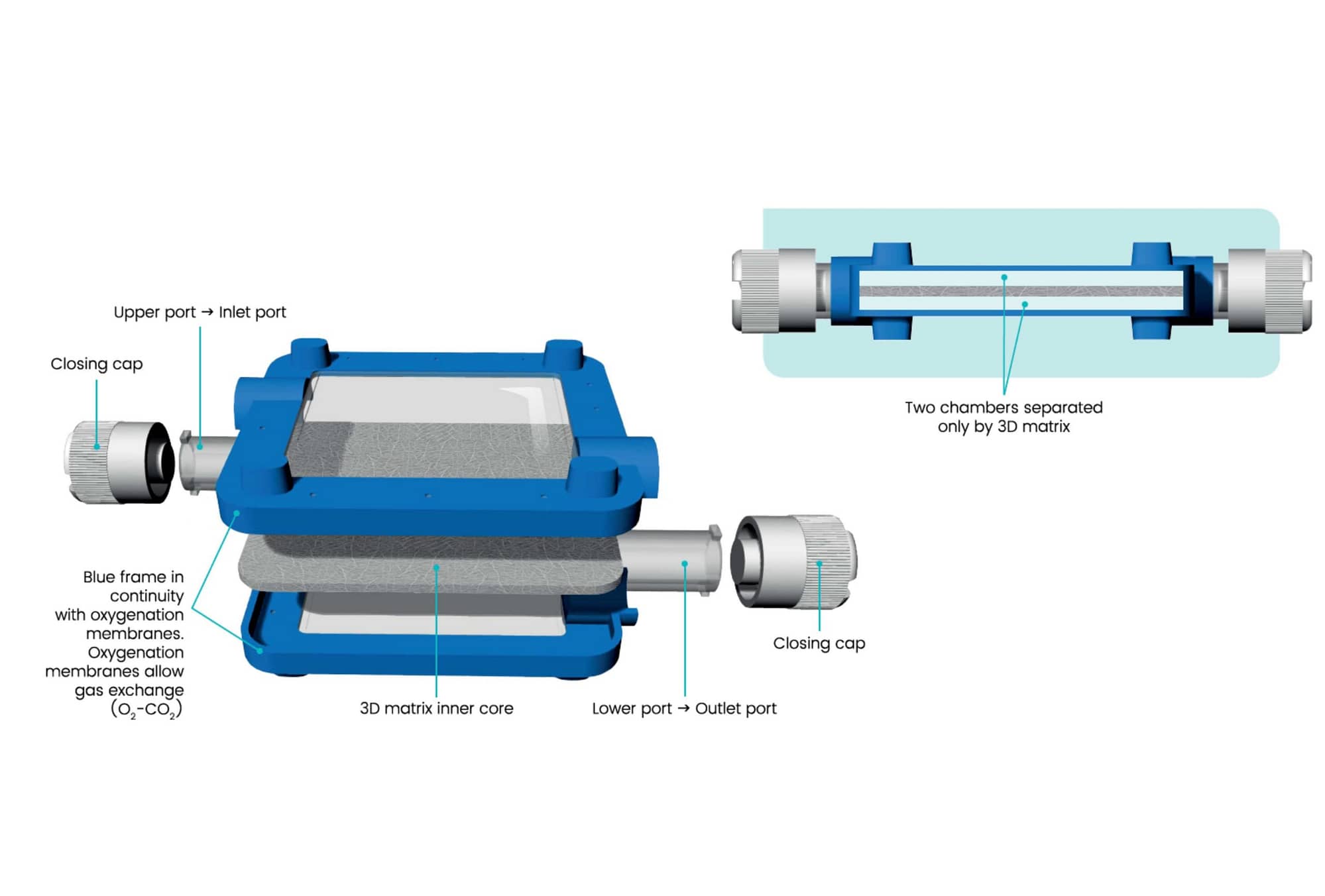

Our VITVO 3D Bioreactor’s matrix inner core is a fiber-based 3D scaffold optimized for cell retainment, engraftment, and colonization. Cells colonize within the 3D matrix by adhering to the fibers, or forming aggregates within its 90% empty volume. Our cell culture bioreactor can host human and animal cells – making it a concrete solution for reducing and replacing small animal studies with both ethical and economic impacts in drug development.

Positioned between the in vitro high throughput screening and the in vivo models, VITVO will reduce costs of drug screening – improving the reliability of pre-clinical safety and efficacy screening.

Features & Benefits

- 3D cultures retain the advantage to mimic an in vivo-like context enabling drug safety and efficacy testing in a human avatar environment

- Fast read-out without the need of a dedicated device (tray fits into a multi-well luminometer)

- Ability to host multiple cell types simultaneously loaded in the two faces

- Can host multiple cell types in a minimal volume

- Respects the biology of the tumor (i.e. antigen expression)

- Ideal for small scale studies

- Portability

- Short-duration use

Documents

Applications

- To address chemotherapy/TKI efficacy in 3D To minimize animal uses (3R)

- To address cell therapies efficacy (possibility to load Targets and Effectors at variable ratios in a 3D relevant model CAR-T, MSC)

- To address biologics efficacy in 3D (PD/PK), i.e tumor penetration of a monoclonal antibody

- To address putative drug toxicity in 3D (hepatocytes)

- To host tumor spheroids (Glioblastoma) also loaded in the two faces

- Cancer metabolomics (i.e. tumor/stroma interaction)

- Histology testing after cell loading (methacrylate embedding)

- Histology testing after cytotoxicity (surrogate of minimal residual disease)

- Migration assays in 3D

- As well as many other applications

Video

Technical Specs

| Material | Device Frame: TPE 3D Matrix: hydrophilically coated PBT Oxygenation Membranes: PMP |

| Size | Matrix volume: 4 cm2 (area) x 400 µm (thickness) Empty volume: 90% of matrix volume |

| Production | The automated fabrication is performed in the clean room, by the innovative technology without any additives and gluing agents |

| Biological safety | Inert, biocompatible and xeno-free DNAse/RNAse free |

| Sterilization | Electron-beam processing |

| Storage and warehousing | Two years shelf life |