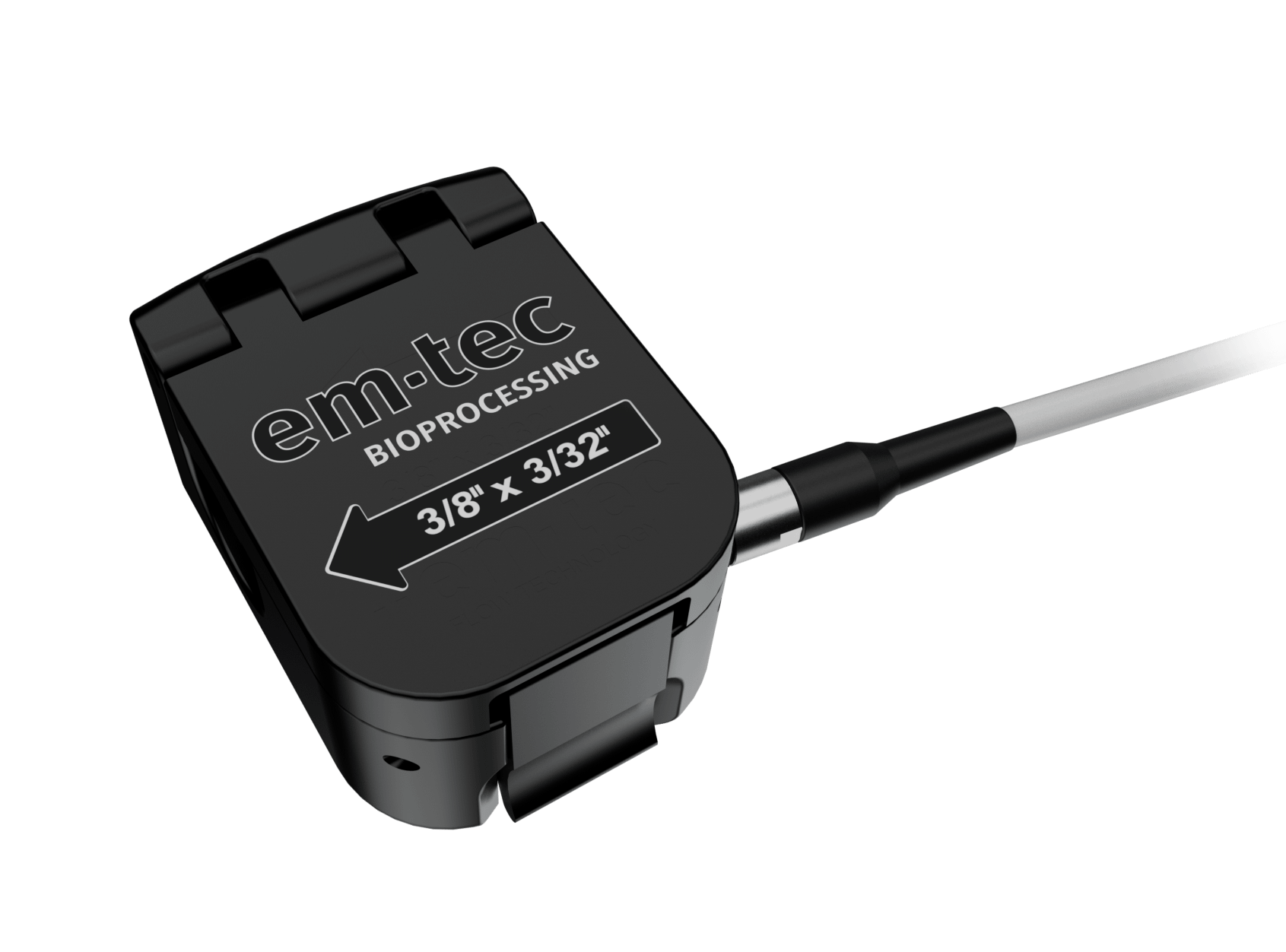

Non-Invasive Ultrasonic Flow Sensor

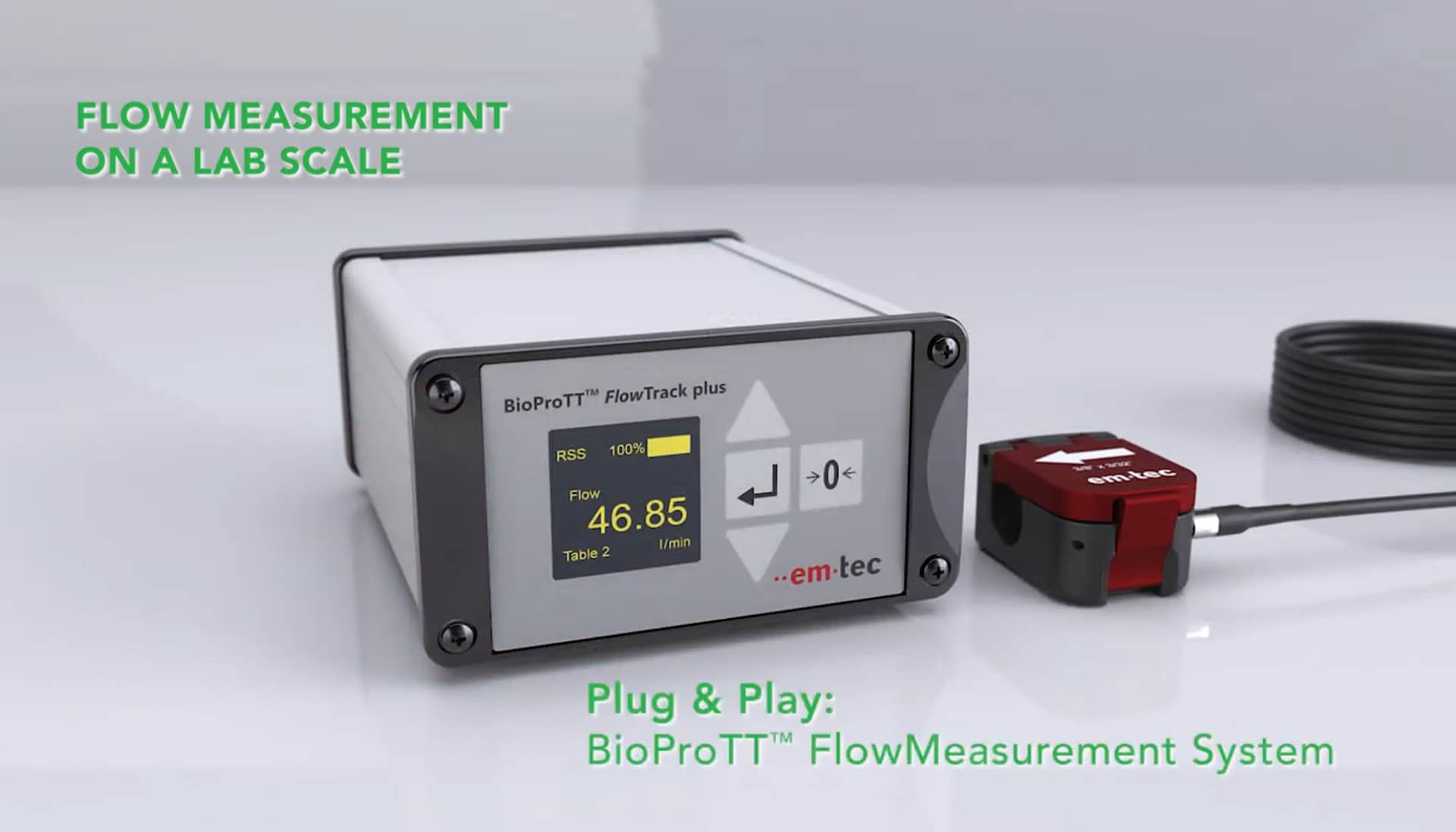

Watch the Video

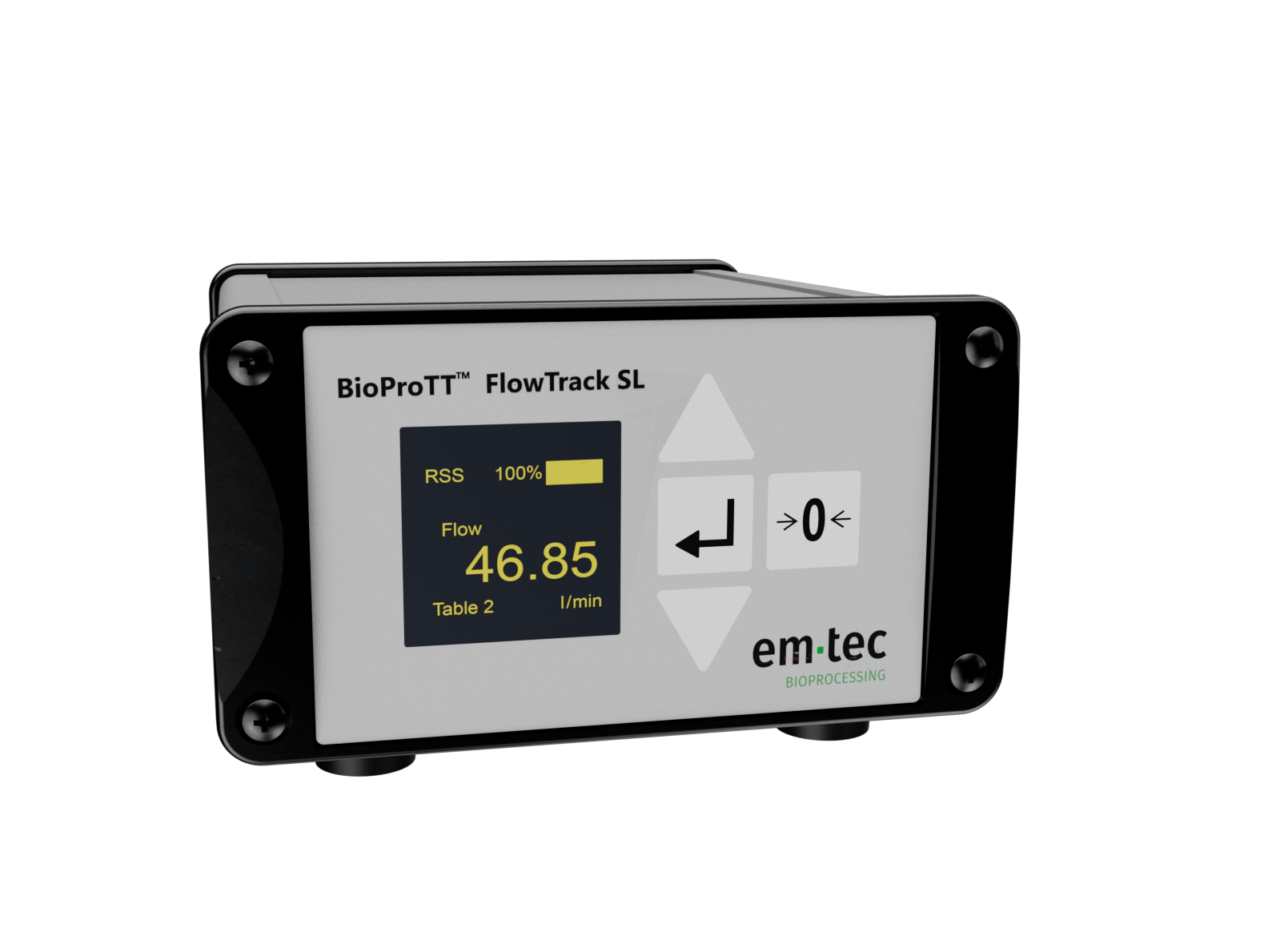

Learn how em-tec provides accurate, intuitive and non-invasive ultrasonic flow sensors for use in biopharmaceutical processing. The BioProTT transducers, with transit-time technology, provide simple, clamp-on flow measurement of tubing systems in the video above.

Space Saving Design

em-tec’s flow meter design allows you to save space and achieve greater accuracy in flow measurement with a non-invasive method. It is extremely compact due to a highly integrated digital electronic design.

Overview

The em-tec flow sensor comes pre-calibrated for the user, requires no priming, and contains the ability to use 7 different calibration tables – all on one sensor. The BioProTT transducer, with transit-time technology, provides simple, clamp-on flow measurement of tubing systems. The transducer quickly and easily clamps around flexible hoses with a click lock. This lock ensures that contamination and pressure-drops within the system will be avoided, as well as no extra assembly splicing.

The functional design of this em-tec flow meter features no moving parts and prevents any additional shearing on the process fluid, giving it a great advantage over invasive methods that also handle biomolecules or shear-sensitive organisms.

Features & Benefits

- Non-invasive

- The transducer encloses flexible tubing with its simple click closure in an effortless, non-invasive way

- Transducers for a wide variety of tubing sizes available

- Customer specific calibration for media, tubing, and temperature

- Up to seven calibration tables can be stored on one sensor, allowing maximum flexibility

- Excellent accuracy and stability

- Water proof, easy to clean, and disinfectable surface

- Easy installation into your current system, allowing for a non-invasive flow measurement

- Different sensor sizes for all common tubing sizes

- Due to the non-invasive design, there is no additional shear stress on cells

- Device designed to be reusable for years

Documents

Applications

- For flow measurement on flexible tubing in upstream and downstream applications

- Filtration steps

- Chromatography

- Harvest applications

- Filling

- Process Evaluation

- Research

- As well as many other applications

Technical Specs

| Features | up to OD 5/8" | up to OD 3/4" | up to OD 1-1/8" | up to OD 1-5/8" |

| Size (HxWxL) | 25 x 33 x 45 mm | 27 x 38 x 51 mm | 35 x 43 x 69 mm | 46 x 56 x 84 mm |

| Weight transducer head | 52 g | 72 g | 140 – 160 g | 295 – 315 g |

| Total weight (incl. cable / plug) | 137 g | 153 g | 225 – 245 g | 380 – 400 g |

| Cable length | 2.9 m | 2.9 m | 2.9 m | 2.9 m |

| IP-Code | IP 67 | IP 67 | IP 67 | IP 67 |

Product Comparison

Non-Invasive

Flow Sensor

- Ultrasonic sensor

- Up to 7 calibration tables

- Compact size

- Waterproof design

- Up to 50C operating temp

- Customer specific calibration

Electromagnetic Flow Sensor

- Accuracy of 1%

- Gamma/Autoclave Stable Flow Tube

- Minimal hold-up volume

- Accommodates two flow tubes

- Full bore flow path

- Factory calibrated

Mass Coriolis

Flow Sensor

- Accuracy: +/- 1% of flow

- Gamma stable PEEK sensor

- For ultra low flow

- Flow pressure of 30 psi

- Designed for measuring liquids

- Materials: Unreinforced polyether ether ketone

Turbine

Flow Sensor

- Stainless steel flow sensor

- Flow range: 0.06 – 40 L/min

- 3 models available

- High accuracy and repeatability

- Infrared (IR) turbine rotor reflection

- Suitable for opaque liquids